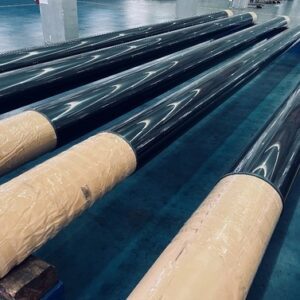

Product Description: HVOF Coating Hydraulic Piston Rod

Our HVOF Coating Piston Rods feature a specially formulated tungsten carbide-cobalt-chromium (WC-CoCr) coating applied using state-of-the-art High Velocity Oxygen Fuel thermal spray technology. This advanced process creates an impermeable, hard, and ductile layer that significantly outperforms traditional chrome plating and other conventional coatings in terms of wear resistance, corrosion protection, and overall durability.

The HVOF process involves burning fuel with oxygen to create a high-velocity gas stream, into which tungsten carbide, cobalt, and chromium powder is injected. The particles become semi-molten and are propelled at high speed toward the piston rod surface, creating a dense, well-bonded coating with exceptional properties. This environmentally friendly alternative to hard chrome plating delivers superior performance while eliminating the use of harmful hexavalent chromium.

Technical Specifications

Parameter: Standard Grade

Base Material: Carbon Steel, Alloy Steel, Stainless Steel

Coating Type: WC-10Co-4Cr

Coating Thickness: 0.003 inches (0.076 mm), 0.005 inches (0.127 mm), 0.01 inches (0.254mm), 0.02 inches (0.508mm) and so on.

Hardness: 1,050-1,250 HV

Bond Strength: >80 MPa (>12,000 PSI)

Young’s Modulus: 300 GPa

Porosity: <0.8%

Surface Roughness: Ra 3.5-4.5 μm (as-sprayed)

Deposition Efficiency: 40-55%

Corrosion Resistance: Excellent

Available Diameters: 20mm to 200mm (custom sizes available)

Available Lengths: Up to 12 meters

Key Features and Benefits of Younglee’s HVOF Coating Piston Rods

• Superior Wear Resistance: Exceptional resistance to sliding wear, abrasion, cavitation, and erosion

• Excellent Corrosion Protection: Significantly outperforms chrome plating in corrosive environments

• High Bond Strength: Exceptional adhesion to the substrate ensures long-term durability

• Low Porosity: Near pore-free density level prevents penetration of corrosive media

• Environmentally Friendly: Free from hexavalent chromium and other harmful substances

• Extended Service Life: Documented cases show 5+ years of service in environments where chrome plating lasted only 6 months

• Reduced Maintenance: Longer service intervals and reduced downtime

• Improved Seal Life: Optimized surface finish for extended seal performance

• Chemical Resistance: Excellent resistance in different environments such as acid, alkaline, and chloride solutions

Applications of HVOF Coating Hydraulic Piston Rod

Our HVOF Coating Piston Rods are specifically designed for applications in harsh and demanding environments, including:

• Marine and Offshore: Deck machinery, cranes, winches, and ROV systems

• Oil and Gas: Drilling equipment, refinery dock cranes, and production systems

• Mining and Construction: Hydraulic excavators, loaders, and heavy machinery

• Steel Industry: Continuous casting machines and hydraulic systems

• Chemical Processing: Pumps, valves, and process equipment

• Pulp and Paper: Hydraulic systems in paper mills

• Power Generation: Hydraulic systems in power plants

-e1677569150106.png)

Reviews

There are no reviews yet.