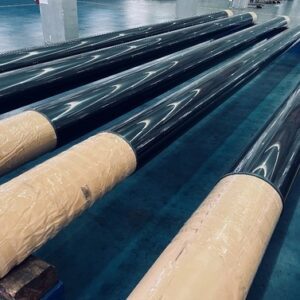

Ceramic Coated Piston Rod Description

Our Ceramic Coated Piston Rods feature a specially formulated ceramic coating applied to high-quality steel substrates using state-of-the-art surface coating technology. The ceramic layer creates an impermeable, hard, and durable surface that outperforms traditional chrome plating and other conventional coatings in terms of longevity, reliability, and environmental resistance.

The Ceramic coating technology employed in our manufacturing process enables us to achieve a corrosion resistance of minimum 1000 hours based on ASTM B117 salt spray test standard, with premium options offering up to 2000 hours of protection.

Technical Specifications

Parameter: Specification

Base Material: Carbon Steel, Alloy Steel, Stainless Steel

Coating Type: Ceramic Composite

Coating Thickness: 0.25mm, 0.30mm, 0.50mm, and custom available.

Hardness: 850-1300 Hv

Bond Strength: Min 40 MPa

Corrosion Resistance (ASTM B117): Min 1000 hour on rating 9, 1500 hour and 2000 hour are available on request.

Impact Resistance: 7-15 Nm

Fracture Force: Min 280 MPa

Surface Roughness: Ra 0.10µm to 0.3µm

Modulus Elasticity: 350 to 400 GPa

Available Diameters: 20mm to 800mm (custom sizes available)

Available Lengths: Up to 16 meters

Key Features and Benefits of Younglee’s Ceramic Coated Piston Rods

• Superior Corrosion Protection: Outperforms traditional chrome plating by 10-20 times in salt spray tests

• Excellent Wear Resistance: Highly resistant to abrasion, extending component life

• Environmentally Friendly: Free from hexavalent chromium and other harmful substances

• Reduced Maintenance: Longer service intervals and reduced downtime

• Improved Seal Life: Optimized surface finish for extended seal performance

• Temperature Resistant: Maintains performance across a wide temperature range

• Chemical Resistance: Withstands exposure to aggressive chemicals and marine environments

• Reduced Friction: Lower coefficient of friction compared to conventional coatings

Applications of Ceramic Coated Piston Rod

Our Ceramic Coated Piston Rods are specifically designed for applications in harsh and corrosive environments, including:

• Marine and Offshore: Deck machinery, cranes, winches, and stabilizers

• Oil and Gas: Drilling equipment, BOP systems, and subsea applications

• Civil Engineering: Flood gates, dams, locks, and heavy machinery

• Mining: Hydraulic supports, excavators, and material handling equipment

• Steel Industry: Continuous casting machines and rolling mill equipment

• Chemical Processing: Pumps, valves, and process equipment

• Waste Management: Compactors and handling equipment

-e1677569150106.png)

Reviews

There are no reviews yet.