-e1677569150106.png)

Coaxial tubing and Coax fittings are the main products of our ultra high purity (UHP) stainless steel tubing & fittings product line. As the top quality China ultra high purity stainless steel tubing & fitting supplier and manufacturer, our company manufactures and supplies full size range of stainless steel coaxial tubing and COAX tube fittings for Handling Special Gases for many industrial applications such as Semiconductors and Microelectronics, and so on.

Photos of Our COAX tubing and Coaxial tube fittings

What is Coaxial stainless steel tubing & COAX tube fittings?

Coaxial stainless steel tubing & fittings are designed for delivery of special gas such as volatile or toxic gases. This product is known as Containment tube also, and is called COAX tube and COAX fitting for short sometimes.

A coaxial tube usually is consist of a process tube and a safety tube. The process tube is the inner tube, while the safety tube is the outer tube. So coaxial tube system is also known as twin wall tube system or double wall tube systems. The function of spacers is to center the process tube and ensure the gas flow between the outer and inner tube. They also act as a safety mechanism in the event of a process tube leak. Any escaping medium flows (gas or liquid) into the safety space, where it can be neutralized and safely discharged from the system.

Process tubes are supplied with the electropolished surface finish and specifications as our single wall electro polished tube and EP fittings. Our factory has a full range types of coaxial tube fittings (a fitting-within-a-fitting) such as 90-degree elbows, 45° elbows, equal tees, reducing tees and reducers.

COAX tubing /Coaxial Tube Fittings: Product Descriptions

As a professional ultra-high purity (UHP) tubing manufacturer & supplier, Younglee Tube produces and supplies COAX stainless steel tubing /Coaxial tube fittings with details as below.

- Material: High quality 316L stainless steel, equivalent EN DIN 1.4404; 304L /1.4307 is available on request.

- Size Range: 1/4″ to 4″ on request

- Surface finish:

The inner tube electro polished with roughness Ra 0.25μm;

The outer tube bright annealed with inner roughness Ra 0.6μm. - Both process tube and safety tube are prepared for orbital welding

Coaxial Tubes and COAX tube fittings are prepared for orbital welding acc. to the following international standards:

- Coaxial Tubes

acc. to ASTM A 269 / A270 / A 632, DIN EN 10217-7 / 10216-5. - Coaxial Tube fittings

Pre-material acc. to ASTM A 269 / A 632, DIN EN 10217-7 / 10216-5

Other standards available upon customers’ request.

Welded or seamless austenitic stainless steel tubes & fittings (for inner process tube and outer safety tube) are available in the following materials:

• 1.4404 / UNS S31603 (316L)

• 1.4435 / UNS S31603 (316L)

• UNS S31603 (316L)

Coaxial stainless steel tube standard size list as below.

| Inner Tube | Outer Tube | ||||

| Imperial Size | OD1 | WT1 | OD2 | WT2 | |

| inch | mm | inch | mm | ||

| 1/4″ | 6.35 | 0.89 | 1/2″ | 12.70 | 1.24 |

| 3/8″ | 9.53 | 0.89 | 5/8″ | 15.88 | 1.24 |

| 1/2″ | 12.7 | 1.24 | 3/4″ | 19.05 | 1.24 |

| 3/4″ | 19.05 | 1.65 | 1″ | 25.40 | 1.24 |

| 1″ | 25.4 | 1.65 | 1.1/2″ | 38.10 | 1.24 |

Other sizes available on customer’s request.

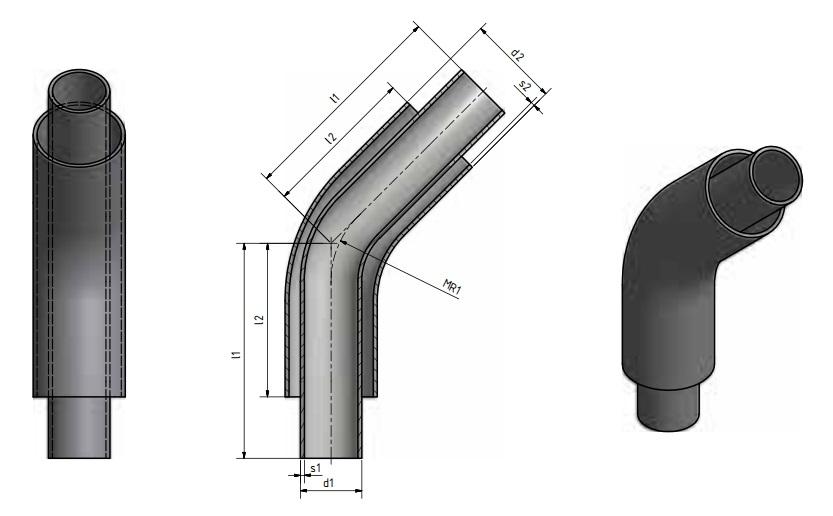

Coaxial Elbow 45°

| Inner tube | Outer Tube | Dimensions | |||||

| Imperial Size | d1 | s1 | d2 | s2 | l1 | l2 | MR1 |

| inch | mm | ||||||

| 1/4″ | 6.35 | 0.89 | 12.70 | 1.24 | 98.45 | 79.40 | 38.10 |

| 3/8″ | 9.53 | 0.89 | 15.88 | 1.24 | 98.45 | 79.40 | 57.00 |

| 1/2″ | 12.70 | 1.24 | 19.05 | 1.24 | 109.26 | 90.21 | 85.00 |

| 3/4″ | 19.05 | 1.65 | 25.40 | 1.24 | 135.61 | 110.21 | 85.00 |

| 1″ | 25.40 | 1.65 | 38.10 | 1.24 | 88.90 | 63.50 | 38.10 |

Other sizes of COAX 45° elbow are available upon customers’ requirements.

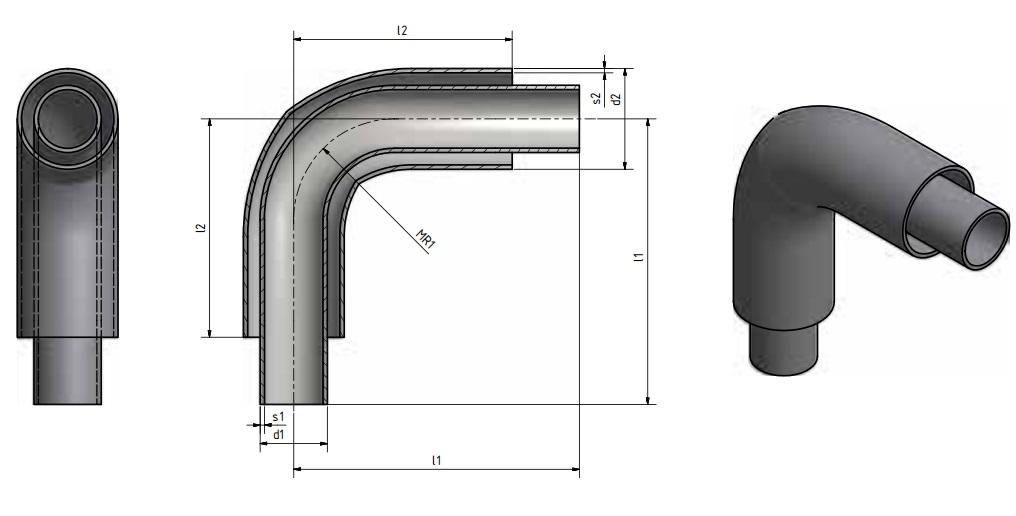

Coax Elbow 90°

| Imperial Size | Inner Tube | Outer Tube | Dimensions | ||||

| d1 | s1 | d2 | s2 | l1 | l2 | MR1 | |

| inch | mm | ||||||

| 1/4″ | 6.35 | 0.89 | 12.70 | 1.24 | 120.70 | 101.65 | 38.10 |

| 3/8″ | 9.53 | 0.89 | 15.88 | 1.24 | 130.70 | 111.65 | 57.00 |

| 1/2″ | 12.70 | 1.24 | 19.05 | 1.65 | 184.40 | 165.35 | 85.00 |

| 3/4″ | 19.05 | 1.65 | 25.40 | 1.65 | 190.75 | 165.35 | 85.00 |

| 1″ | 25.40 | 1.65 | 38.10 | 1.65 | 107.97 | 82.57 | 38.10 |

Besides the above sizes, other sizes of COAX 90° Elbow are available upon customers’ requirements.

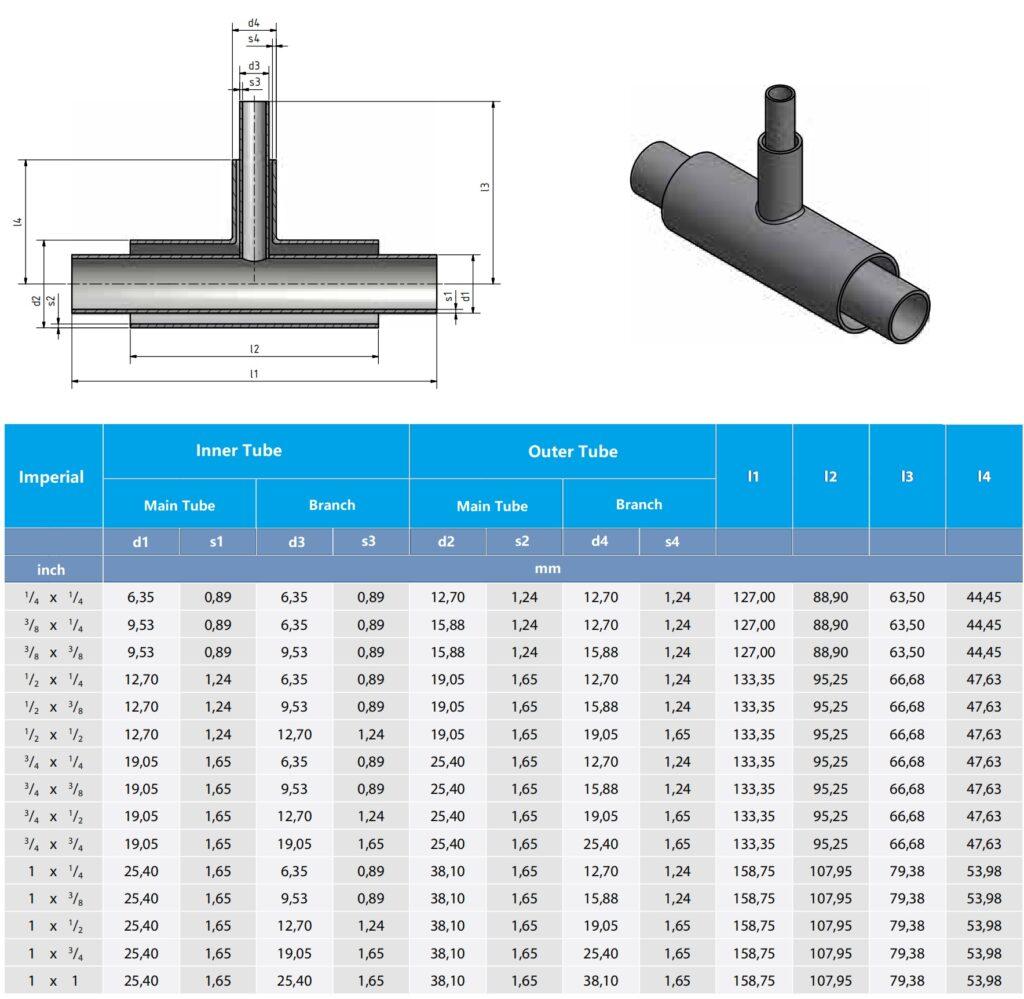

Coax Tee

Here below is the size chart of equal coaxial tee and reducing COAX tee.

Besides the above sizes, other sizes of COAX Tee are available upon customers’ requirements.

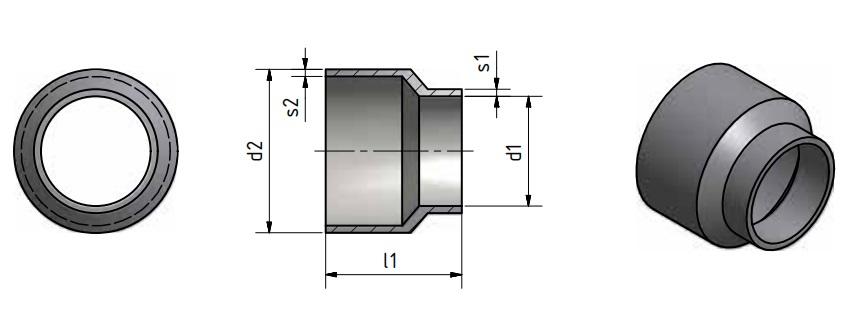

Coaxial Reducer

Coaxial reducer is consist of an Electropolished inner reducer and a bright annealed outer reducer. Here below is the dimension chart.

| Imperial Size | Inner Tube | Outer Tube | Dimensions | ||

| d1 | s1 | d2 | s2 | l1 | |

| inch | mm | ||||

| 1/4″ | 6.35 | 0.89 | 12.70 | 1.24 | 25.40 |

| 3/8″ | 9.53 | 0.89 | 15.88 | 1.24 | 25.40 |

| 1/2″ | 12.70 | 1.24 | 19.05 | 1.65 | 25.40 |

| 3/4″ | 19.05 | 1.65 | 25.40 | 1.65 | 31.75 |

| 1″ | 25.40 | 1.65 | 38.10 | 1.65 | 31.75 |

Other dimensions available upon customers’ requests.

The surface finishing of the process tube (inner tube) and safety tube (outer tube) of the coaxial stainless steel tubing & COAX tube fittings are as below.

| Finishing | Specifications | Choice of | Surface Roughness | ||

| ASTM/JIS | Pre-Materials | (Max) | |||

| EP /Electro-polished (Inner Tube) | A213/A269 | SUS316L /1.4404 | ID | < 10 RA | < 0.25 μm |

| JIS G3459 | OD | < 32 RA | < 0.8 μm | ||

| BA / Bright annealed (Outer Tube) | A213/A269 | SUS316L /1.4404 | ID | < 25 RA | < 0.63 μm |

| JIS G3459 | SUS316L /1.4404 | OD | < 32 RA | < 0.8 μm | |

If customer agrees or wishes, we will mark each coaxial tube and COAX fitting with laser marking, the marking usually including:

- Manufacturer Name: Younglee (if the customer requests, we can also mark with their brand name)

- Product Name: Tube / 90° elbow / 45° elbow / equal tee / reducing tee/ reducer.

- Specification Standard as: ASTM A269/ A632/ A270; EN 10216-5

- Steel Grade: 316L / 1.4404

- Product Size: O.D x W.T x length (for tube)

- Heat Number.

Quality and Inspection procedures for Coaxial tubing & fittings:

- Visual Inspection

- Endoscopic inspection of bright finished tubes

- Dimensions inspection

- Roughness measurements

- Chemical Analysis: Spectral analysis

- Mechanical properties test

Documentation, Packing and Shipping for COAX Tubing & fitings

- All coxial tubing and fittings are supplied with Younglee’s Mill Test Certificate according to EN 10204 /3.1;

- Each Coaxial tube & fitting will be capped in the ends of the inner tube with plastic caps, every tube and fitting is packed individually in polyethylene bags.

- The coaxial tubes are delivered in a tubular container or wooden case, while the coaxial stainless steel fittings are packaged in a sturdy cardboard box with shock-absorbing filler to protect them during transportation.

- We can ship the stainless-steel tubes and fittings to customers over all the world by sea or by air up on request.

Applications of COAX Tube /Coaxial tube fittings

COAX stainless steel tubing and coaxial stainless steel tube fittings are used for applications where needs to delivery hazardous, volatile, and special medium flows such as toxic, explosive and corrosive medias.

Some common applications for Coaxial stainless steel tubing & fittings include:

Semiconductor manufacturing: COAX tubing &Fittings is used in the fabrication of semiconductor components and devices, where the transport of toxic, explosive and corrosive media is required, and the high purity and cleanliness of the materials are critical to the performance of the final product.

Biopharmaceutical manufacturing: COAX stainless steel tubing & fittings are used in the production of biopharmaceuticals, where the transporting of toxic, explosive and corrosive media is required, and the purity and cleanliness of the materials are critical to ensure the safety and efficacy of the final product.

Chemical processing: COAX tubing & fittings are used in chemical processing applications where the purity and corrosion resistance of the materials are important to prevent contamination and ensure the integrity of the process, and where the transporting of toxic, explosive and corrosive media is required.

Why Choose Us?

As a leading China Ultra-high purity (UHP) stainless steel tubing manufacturer and supplier, customers choose our product of coaxial stainless steel tubing and COAX tube fittings mostly for the product and service advantages as below.

Advantages of our products and services:

- Cleanroom packaging

- Top quality raw materials

- Our raw material stainless steel is sourced from China’s top quality stainless steel manufacturers, such as Baosteel, Tisco, and Youngxing.

- Professional inspection facilities:

Our factory has a variety of professional inspection facilities, including:- Scanning Electron Microscope (SEM)

- Energy Dispersive Spectroscopy (EDS)

- Particle Counter

- Surface Roughness Gauge

- Micro Vickers

- Metallography Microscope

- Moisture Analyzer

- Tensile Testing Machined, etc.

- High purity, cleanliness, and smoothness:

- Our UHP & high purity tubes and pipes are characterized by high levels of purity, cleanliness, and smoothness.

- Highest corrosion resistant performance:

- Our tubing boasts high corrosion resistance performance, making it ideal for a range of applications.

- Suitable for orbital welding:

- Our tubing is suitable for orbital welding, making it easier to use and more versatile.

- Full size range and accept customized size:

- We offer a full range of sizes and accept customized sizes to meet our customers’ specific requirements.

- Flexible and fast delivery time:

- Our factory provides flexible and fast delivery times, designed to meet the demands of today’s fast-paced business world.

9. TQM Quality Management system to ensure the quality:

- All working processes are under control by our Total Quality Management system, which ensures that the quality of our high purity & UHP tubes and pipes meet customers’ requirements 100%.

We also produce and supply:

- High purity stainless steel tubing

- Ultra-high purity (UHP) stainless steel tubing

- High purity stainless steel fittings

- Ultra high purity stainless steel fittings

- Electro polished stainless steel tubing and fittings

Contact us now for more details about our products or get a quote!

Contact Person: Osmond Lee

E-mail: [email protected]

Tel: +86-1861-2706-695