-e1677569150106.png)

Ultra high purity stainless steel fittings are widely used to convey ultra-high purity gases or liquids for many precision and high-tech industries, such as Semiconductor industry, Microelectronic industry, optics, and aerospace industries, and so on.

As a top quality China ultra-high purity fittings &tubing manufacturer and supplier, Younglee factory produces full range of ultra high purity fittings of stainless steel (other material available on request) with details as below.

Ultra High Purity stainless steel fittings Overview

Ultra high purity stainless steel fittings usually is known as ultra-high purity fittings or UHP fittings for short sometimes. They are stainless steel tube fittings with inner surface electro polished finishing, and with ultra high purity.

- Product Name: Ultra high purity stainless steel fittings, UHP tube fittings, ultra-high purity fittings

- Product types: UHP 90° Elbow, 45° UHP Elbow, UHP Tee, UHP Reducers

- Materials: Stainless steel 316L / EN DIN 1.4404; other steel grades are available upon requests

- Inner surface finishing: Elector-polished, with roughness Ra <=0.25μm;

- Outer surface finishing: mechanical polished, with roughness Ra<0.8μm;

-

The UHP fittings are suitable for orbital welding;

-

Size Range available: Metric size OD 6 mm to O.D 154 mm; imperial size 1/4 inch to 6 inch;

-

UHP tube fittings Marking: Brand Name, Size (OD x WT), Material, Product Standard, and Heat No.

-

Packing of the UHP fittings: All fitting ends are capped with plastic caps, each tube fitting packed in a separated bag. We offer packing in clean room upon customer’s request.

Material Specifications

The most popular material for ultra high purity stainless steel fittings is stainless steel TP 316L, this material is also equivalent to EN DIN 1.4404.

Here below is the material data sheet.

Chemical Compositions

| Element | Content (% wt) |

|---|---|

| Carbon (C) | 0.035 Max. |

| Silicon (Si) | 1.00 Max. |

| Manganese (Mn) | 2.00 Max. |

| Phosphorous (P) | 0.045 Max. |

| Sulfur (S) | 0.015 |

| Chromium (Cr) | 16.50 – 18.50 |

| Nickel (Ni) | 10.00 – 13.00 |

| Nitrogen (N) | 0.10 Max. |

| Molybdenum (Mo) | 2.00 – 2.50 |

| Iron (Fe) | Balance |

Data sheet / Catalogue Sheet of Ultra high purity fittings

Here are the dimension chart (data sheet) of our ultra high purity fittings including 90-degree elbows, 45 degree elbows, tees and reducers.

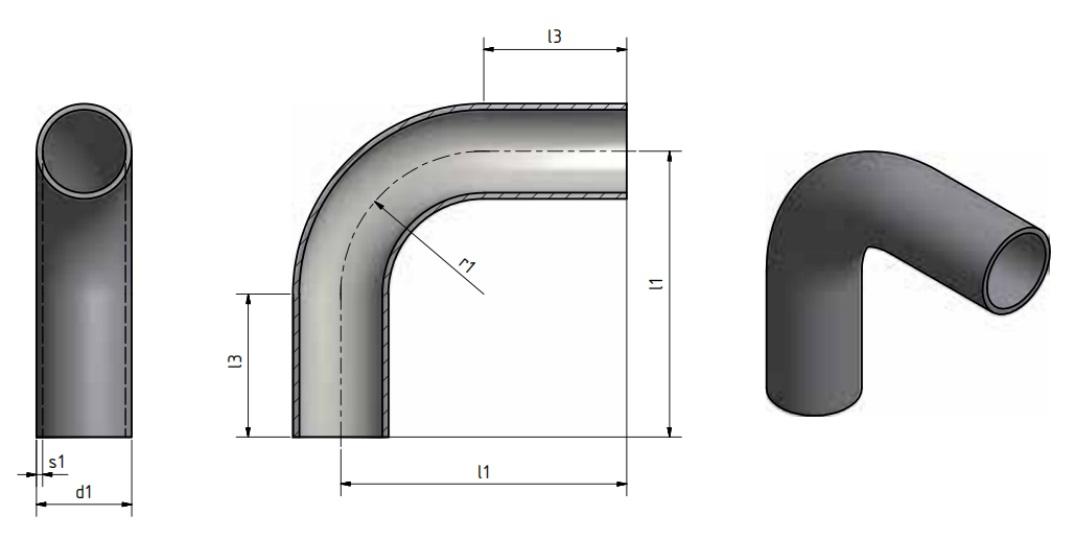

Dimensions of UHP 90° Elbow

Imperial sizes UHP 90-degree elbows:

| Imperial Size | d1 | s1 | l1 | l3 | r1 |

| inch | mm | ||||

| 1/4″ | 6.35 | 0.89 | 66.70 | 52.40 | 14.30 |

| 3/8″ | 9.53 | 0.89 | 66.70 | 38.10 | 28.60 |

| 1/2″ | 12.70 | 1.24 | 76.20 | 49.20 | 27.00 |

| 1/2″ | 12.70 | 1.65 | 76.20 | 47.60 | 28.60 |

| 3/4″ | 19.05 | 1.24 | 76.20 | 50.20 | 26.00 |

| 3/4″ | 19.05 | 1.65 | 76.20 | 47.60 | 28.60 |

| 1″ | 25.40 | 1.65 | 76.20 | 38.10 | 38.10 |

| 1.1/2″ | 38.10 | 1.65 | 95.30 | 38.10 | 57.20 |

| 2″ | 50.80 | 1.65 | 120.70 | 44.50 | 76.20 |

| 2.1/2″ | 63.50 | 1.65 | 139.70 | 44.50 | 95.30 |

| 3″ | 76.20 | 1.65 | 158.80 | 44.50 | 114.30 |

| 4″ | 101.60 | 2.11 | 203.20 | 50.80 | 152.40 |

| 6″ | 152.40 | 2.77 | 292.10 | 63.50 | 228.60 |

| 6″ | 152.40 | 2.77 | 355.60 | 127.00 | 228.60 |

Metric size Ultra high purity 90-degree elbows:

| Metric Size | d1 | s1 | l1 | l3 | r1 |

| mm | mm | ||||

| 6.00 | 6.00 | 1.00 | 40.00 | 24.00 | 16.00 |

| 8.00 | 8.00 | 1.00 | 45.00 | 21.00 | 24.00 |

| 8.00 | 8.00 | 1.00 | 45.00 | 25.00 | 20.00 |

| 10.00 | 10.00 | 1.00 | 45.00 | 25.00 | 20.00 |

| 10.00 | 10.00 | 1.00 | 50.00 | 25.00 | 25.00 |

| 12.00 | 12.00 | 1.00 | 51.00 | 25.00 | 26.00 |

| 13.00 | 13.00 | 1.50 | 51.00 | 25.00 | 26.00 |

| 15.00 | 15.00 | 1.50 | 51.00 | 25.00 | 26.00 |

| 18.00 | 18.00 | 1.50 | 51.00 | 25.00 | 26.00 |

| 19.00 | 19.00 | 1.50 | 60.00 | 25.00 | 35.00 |

| 23.00 | 23.00 | 1.50 | 65.00 | 25.00 | 40.00 |

| 28.00 | 28.00 | 1.50 | 90.00 | 40.00 | 50.00 |

| 30.00 | 30.00 | 1.50 | 90.00 | 40.00 | 50.00 |

| 35.00 | 35.00 | 1.50 | 95.00 | 40.00 | 55.00 |

| 40.00 | 40.00 | 1.50 | 100.00 | 40.00 | 60.00 |

| 53.00 | 53.00 | 1.50 | 110.00 | 40.00 | 70.00 |

| 70.00 | 70.00 | 2.00 | 120.00 | 40.00 | 80.00 |

| 85.00 | 85.00 | 2.00 | 145.00 | 55.00 | 90.00 |

| 104.00 | 104.00 | 2.00 | 155.00 | 55.00 | 100.00 |

| 154.00 | 154.00 | 2.00 | 325.00 | 100.00 | 225.00 |

Dimensions of 45° UHP Elbow

Imperial sizes UHP 45-degree elbows:

| Imperial Size | d1 | s1 | l2 | r1 |

| inch | mm | |||

| 1/4″ | 6.35 | 0.89 | 50.80 | 14.30 |

| 3/8″ | 9.53 | 0.89 | 50.80 | 28.60 |

| 1/2″ | 12.70 | 1.24 | 57.20 | 27.00 |

| 1/2″ | 12.70 | 1.65 | 57.20 | 28.60 |

| 3/4″ | 19.05 | 1.24 | 57.20 | 26.00 |

| 3/4″ | 19.05 | 1.65 | 57.20 | 2.60 |

| 1″ | 25.40 | 1.65 | 57.20 | 38.10 |

| 1.1/2″ | 38.10 | 1.65 | 63.50 | 57.20 |

| 2″ | 50.80 | 1.65 | 76.20 | 76.20 |

| 2.1/2″ | 63.50 | 1.65 | 85.70 | 95.30 |

| 3″ | 76.20 | 1.65 | 92.10 | 114.30 |

| 4″ | 101.60 | 2.11 | 114.30 | 152.40 |

| 6″ | 152.40 | 2.77 | 158.80 | 228.60 |

| 6″ | 152.40 | 2.77 | 222.25 | 228.60 |

Metric size Ultra high purity 45-degree elbows:

| Metric Size | d1 | s1 | l2 | r1 |

| mm | mm | |||

| 6.00 | 6.00 | 1.00 | 32.10 | 16.00 |

| 8.00 | 8.00 | 1.00 | 32.10 | 13.50 |

| 8.00 | 8.00 | 1.00 | 32.10 | 24.00 |

| 10.00 | 10.00 | 1.00 | 33.30 | 20.00 |

| 10.00 | 10.00 | 1.00 | 33.30 | 24.00 |

| 12.00 | 12.00 | 1.00 | 35.80 | 26.00 |

| 13.00 | 13.00 | 1.50 | 35.80 | 26.00 |

| 15.00 | 15.00 | 1.50 | 35.80 | 26.00 |

| 18.00 | 18.00 | 1.50 | 35.80 | 26.00 |

| 19.00 | 19.00 | 1.50 | 39.50 | 35.00 |

| 23.00 | 23.00 | 1.50 | 41.60 | 40.00 |

| 28.00 | 28.00 | 1.50 | 60.70 | 50.00 |

| 30.00 | 30.00 | 1.50 | 60.70 | 50.00 |

| 35.00 | 35.00 | 1.50 | 62.00 | 55.00 |

| 40.00 | 40.00 | 1.50 | 64.90 | 60.00 |

| 53.00 | 53.00 | 1.50 | 69.00 | 70.00 |

| 70.00 | 70.00 | 2.00 | 73.10 | 80.00 |

| 85.00 | 85.00 | 2.00 | 92.30 | 90.00 |

| 104.00 | 104.00 | 2.00 | 96.40 | 100.00 |

| 154.00 | 154.00 | 2.00 | 193.20 | 225.00 |

Other sizes available upon customers’ requirements.

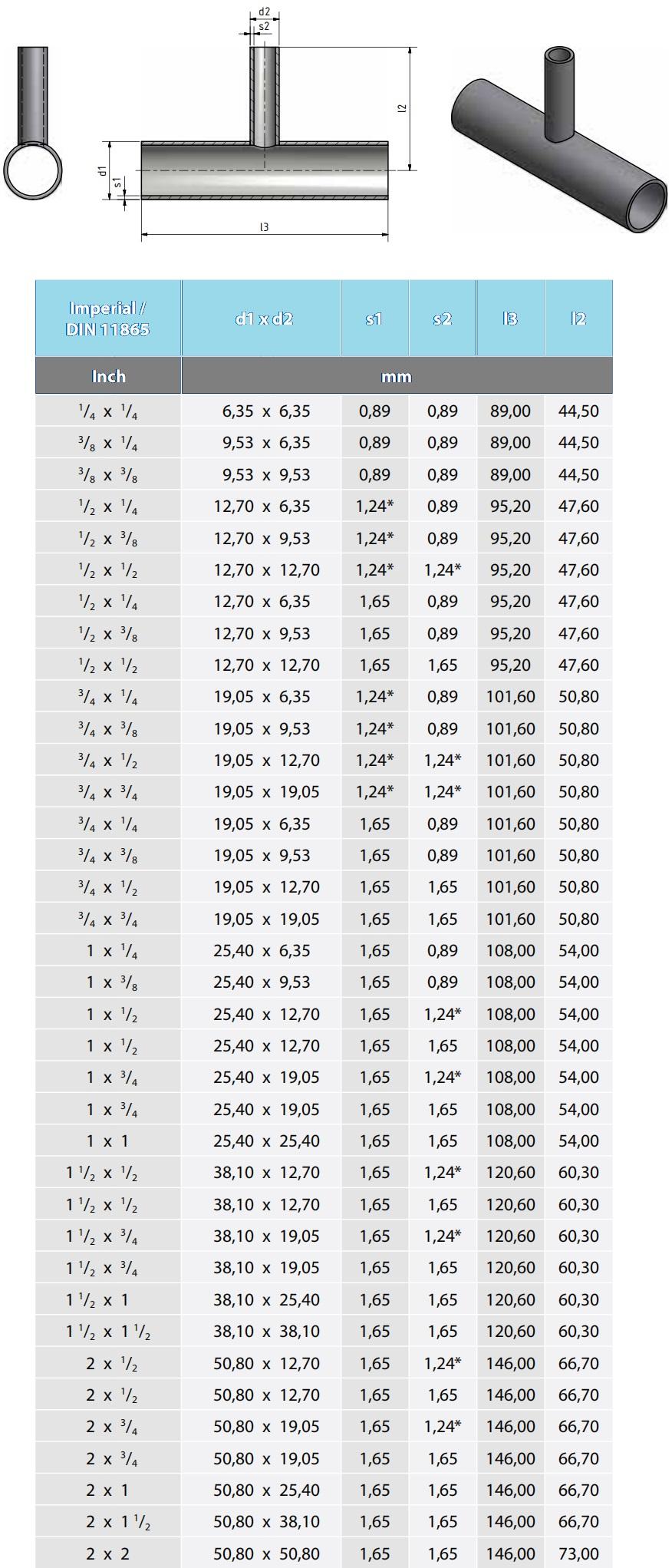

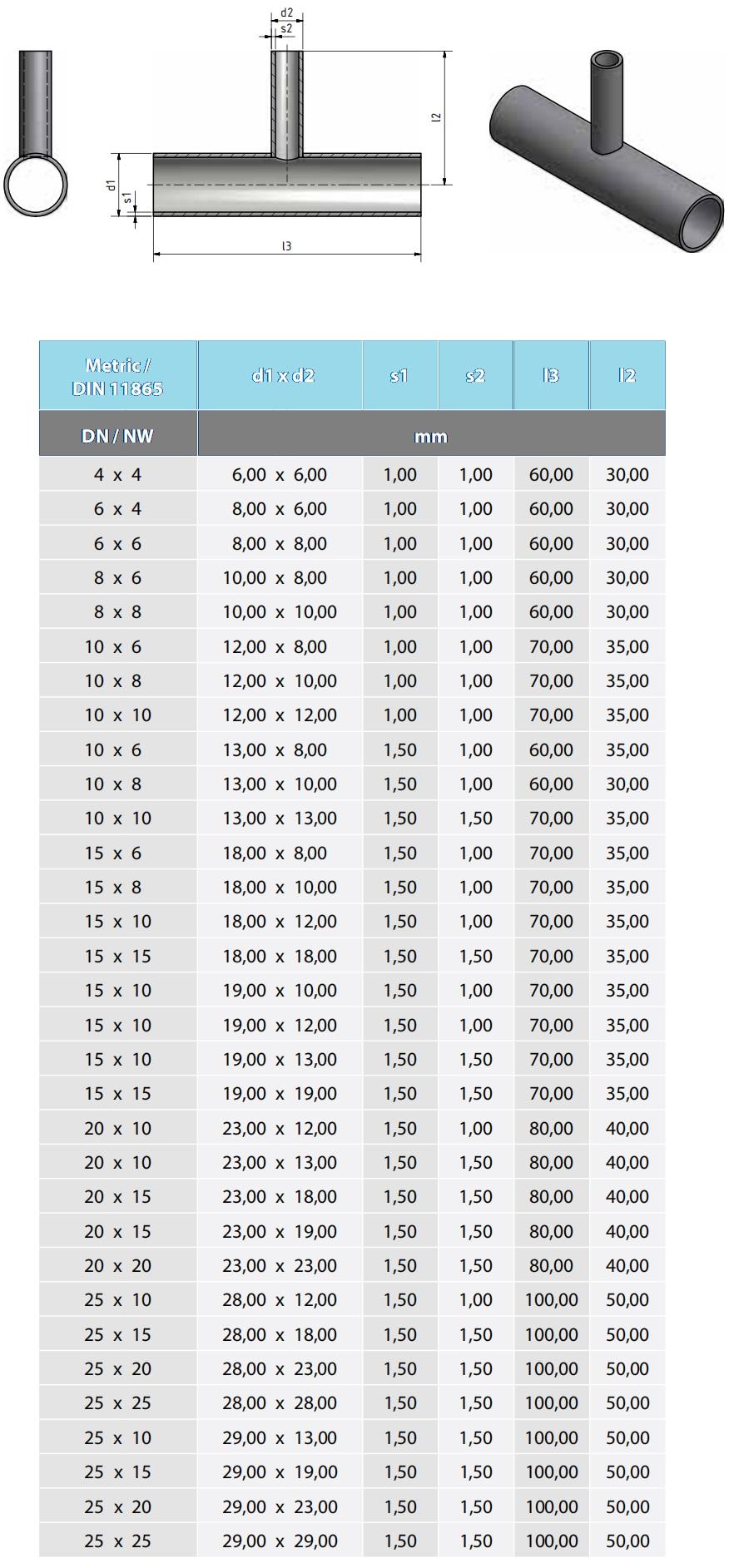

Dimensions of UHP Tee

Other imperial dimensions are available upon customers’ requests.

Other metric dimensions are available upon customers’ requests.

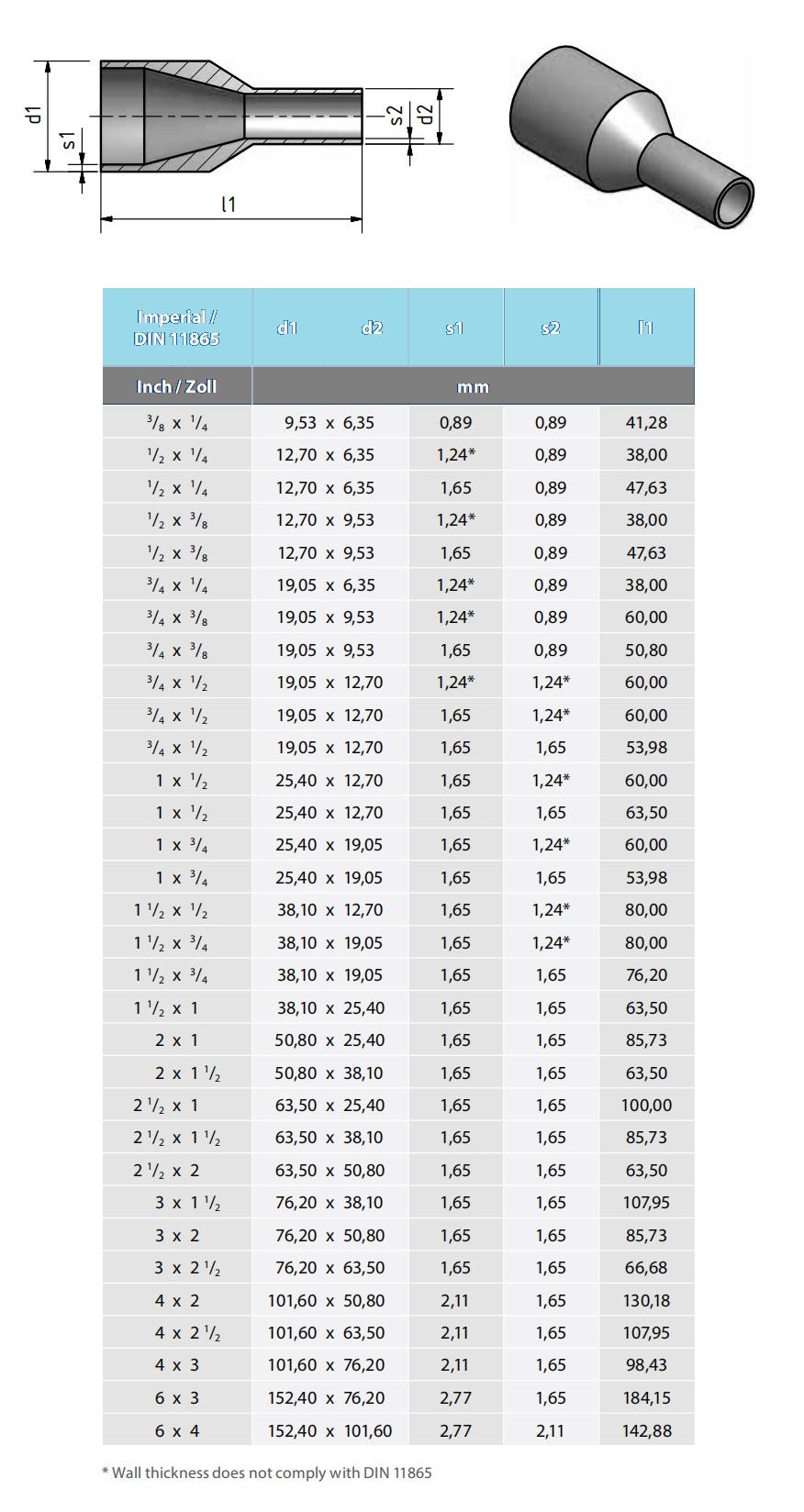

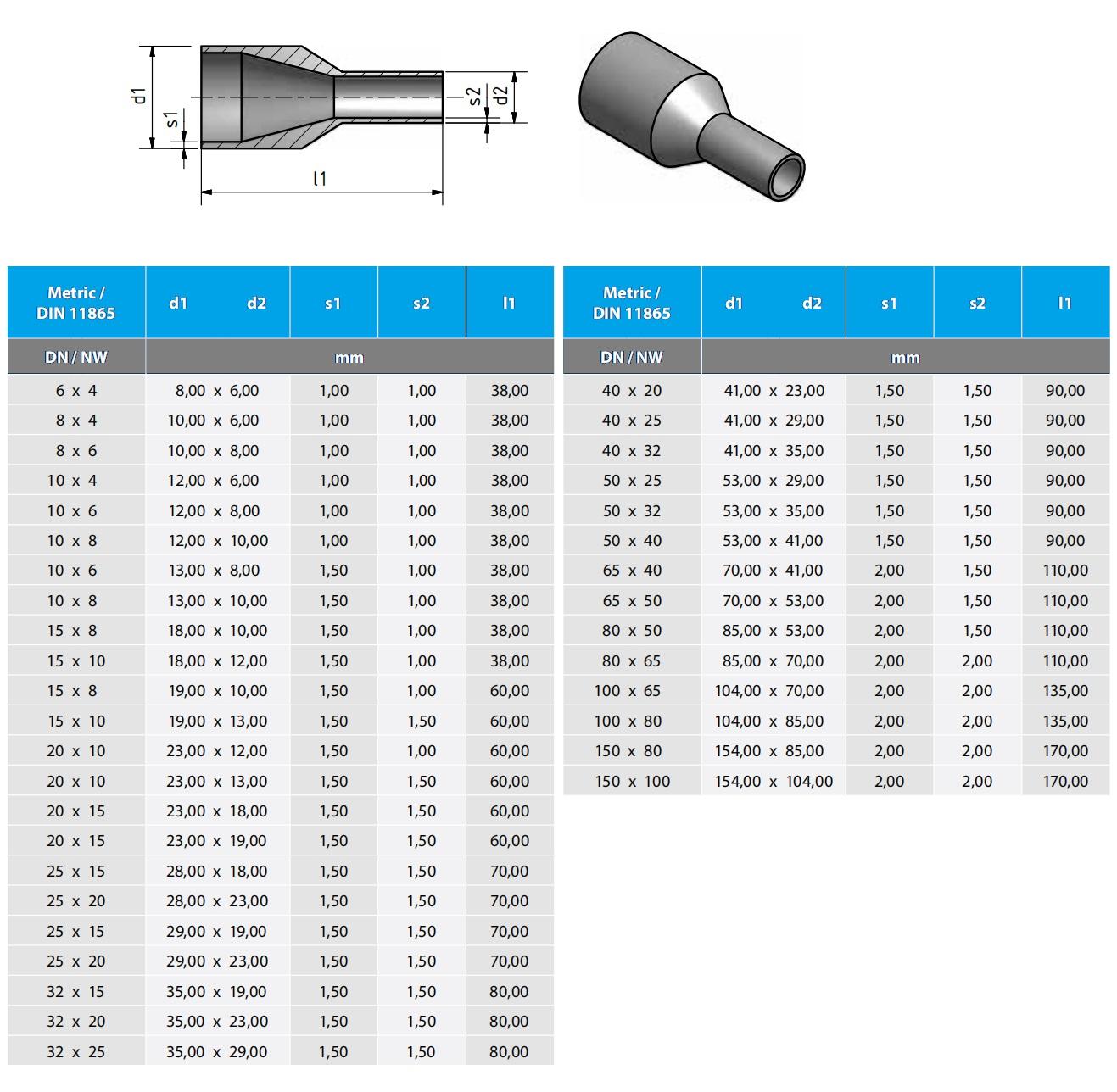

Dimensions of UHP Reducer

Other imperial dimensions are available upon customers’ requests.

Other metric sizes are available up on customers’ requests.

Ultra high purity (UHP) fittings are used in a wide range of industries that require the highest level of cleanliness and purity, such as semiconductor manufacturing, biopharmaceuticals, optics, and electronics.

Some common applications of ultra high purity fittings include:

- Gas delivery systems: ultra-high purity stainless steel fittings are used to transfer ultra-high purity gases, such as nitrogen, argon, and oxygen, in gas delivery systems.

- Liquid transfer systems: ultra high purity tube fittings are also used in liquid transfer systems for ultra high-purity liquids, such as solvents, acids, and bases.

- Vacuum systems: UHP fittings are used to create and maintain a vacuum in high-purity vacuum systems, such as those used in semiconductor manufacturing and research.

- Analytical instrumentation: ultra-high purity tube fittings are used in analytical instrumentation, such as gas chromatography, mass spectrometry, and liquid chromatography, where even the slightest impurities can affect the accuracy of the analysis.

-

Semiconductor manufacturing: ultra-high purity fittings are used to transport gases and liquids in the production of microelectronics, such as integrated circuits and computer chips.

-

Biopharmaceuticals: ultra-high purity stainless steel fittings are used in the production of pharmaceuticals, vaccines, and other biologics where purity is critical to ensure the safety and efficacy of the product.

-

Aerospace and defense: UHP tube fittings are used in aerospace and defense applications where high-performance materials and components are required to meet stringent specifications and standards.

-

Food and beverage: UHP tube fitting is used in food and beverage processing, particularly in the production of high-quality and specialty products.

-

Renewable energy: Ultra high purity fittings & tubing are used in the production of renewable energy technologies, such as fuel cells and solar panels, where purity and performance are critical to the success of the technology.

Why Choose Us?

As a leading China Ultra-high purity fittings & tubing manufacturer and supplier, customers choose our product of ultra high purity stainless steel fittings mostly for the product and service advantages as below.

Advantages of our products and services:

- Cleanroom packaging available

- Ultra High purity, cleanliness, and smoothness:

-

Suitable for orbital welding:

Our UHP fittings are suitable for orbital welding, making it easier to use and more versatile.

- Top quality raw materials

We source our raw material stainless steel from leading Chinese manufacturers, including Baosteel, Tisco, and Youngxing, known for producing top-quality stainless steel.

- Professional inspection facilities:

Our factory has a variety of professional inspection facilities, including Scanning Electron Microscope (SEM), Energy Dispersive Spectroscopy (EDS), Particle Counter, Surface Roughness Gauge, Micro Vickers, Metallography Microscope, Moisture Analyzer, Tensile Testing Machined, etc. – all of which enable us to carry out thorough inspections with precision and accuracy.

- Highest corrosion resistant performance:

With its exceptional resistance to corrosion, our UHP tube fittings are well-suited for a wide variety of applications.

- Full dimension range and accept customized dimensions:

To meet our customers’ specific requirements, we provide a complete range of sizes and accept customized sizes.

- Flexible and quick lead time:

We offer quick and flexible lead times from our factory to meet the demands of the fast-paced business world.

- TQM Quality Management system to ensure the quality:

Our Total Quality Management system controls all working processes to ensure the quality of our ultra high purity and high purity fittings & tubing meets customers’ request 100%.

Our ultra high purity tube fittings are supplied to many customers in many countries such as USA, Singapore, Korea, Chile, Argentina, Australia, and a lot of European countries.

Get A Quotation Now!

Our products are interchangeable with the worlds famous brands!

Contact us now for pricing or information to any other questions.

E-mail: [email protected]

Click Here