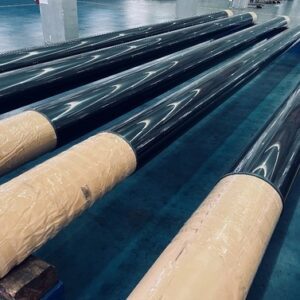

Product Description

Our Alumina-Titania Coating Piston Rods feature a specially formulated aluminum oxide combined with titanium oxide thermal spray coating. This advanced ceramic composite material creates a durable surface layer that effectively protects against thermal shock and mechanical friction, making it ideal for applications where conventional coatings would rapidly deteriorate.

The coating is applied using state-of-the-art thermal spray technology, which ensures optimal adhesion and uniform coverage. Available in multiple composition ratios of Al₂O₃ and TiO₂, our piston rods can be tailored to meet specific application requirements, providing the perfect balance of hardness, conductivity, and thermal shock resistance for your particular operating environment.

Technical Specifications

Parameter: Specification

Base Material: Carbon Steel, Alloy Steel, Stainless Steel

Coating Type: Alumina-Titania Ceramic Composite

Chemical Compositions Available: Type 1: Al₂O₃ 87%, TiO₂ 13%Type 2: Al₂O₃ 60%, TiO₂ 40%Type 3: Al₂O₃ 50%, TiO₂ 50%(Custom compositions available)

Coating Thickness: Custom, upon customers’ request

Bond Strength: 4100 PSI

Hardness: 1000HV-1200HV

Thermal Expansion Coefficient: 6.3×10⁻⁶ (21-1090°C)

Thermal Conductivity: 2.8 W/m·K (540-1090°C)

Acid Resistance: Good

Thermal Shock Resistance: Good

Color: Light Green

Available Diameters: 20mm to 800mm (custom sizes available)

Available Lengths: Up to 10 meters

Key Features and Benefits of Younglee’s Alumina-Titania Coating Piston Rods

• Superior Thermal Shock Resistance: Withstands rapid temperature changes without cracking or delamination

• Excellent Mechanical Friction Protection: Reduces wear in high-friction applications

• Adjustable Conductivity: With increasing TiO₂ content, the conductivity increases to meet specific requirements

• Heat Resistant: Maintains performance at temperatures up to 540°C (1000°F)

• Chemical Resistance: Resistant to most acids and alkalies

• High Dielectric Strength: Suitable for applications requiring electrical insulation

• Customizable Properties: Multiple composition options to optimize performance for specific applications

• Smooth Surface Finish: Provides excellent sealing compatibility and reduced friction

• Extended Service Life: Significantly increases the operational life of hydraulic systems

• Environmentally Friendly: Free from hexavalent chromium and other harmful substances

Applications

Our Alumina-Titania Coating Piston Rods are specifically designed for applications requiring thermal shock resistance and protection against mechanical friction:

Industrial Applications

• Plate cylinders

• Screw shafts

• Sleeve shafts

• Pump shafts

• Hydraulic cylinders in high-temperature environments

Textile Industry

• Heater plates

• Thread guides

• Draw rolls

• Thread wheels

• Tension washers

• Creel rolls

Chemical Industry

• Bearing surfaces

• Process equipment components

• Valves and actuators

• Pumps and agitators

Other Applications

• Thermo-couples jackets

• High-temperature processing equipment

• Applications requiring smooth and dense deposits with high friction resistance

-e1677569150106.png)

Reviews

There are no reviews yet.