High Purity Tubing & Ultra-high Purity Stainless Steel Tubing: Product Overview

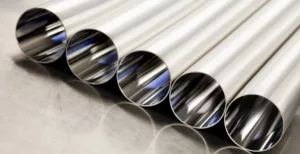

High purity tubing usually refers to high purity stainless steel tubing. High purity tubing and ultra high purity (UHP) stainless steel tubing is the main product group of the electropolished (EP) stainless steel tubing of our high performance stainless steel tubing factory. As one of the leading high purity stainless steel tubing & EP (Electropolishing) stainless steel tubing manufacturer, our factory produces and supplies high purity and ultra high purity stainless steel tubing as below.

■ Seamless cold finished tubes

■ Material: 316L stainless steel, equivalent EN DIN 1.4404;

■ Bright annealed, Mechanical Polished or Elector-polished;

■ High Purity tubing and Ultra high-purity tubing

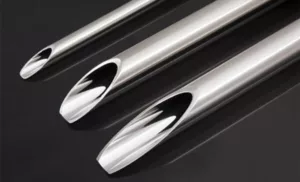

■ Tubes are suitable for orbital welding

■ Size Range: Metric size OD 5 mm to O.D 50 mm; imperial size 1/4 inch to 2 inch

■ Tube Marking: Size (OD x WT), Material, Product Standard, and heat No.

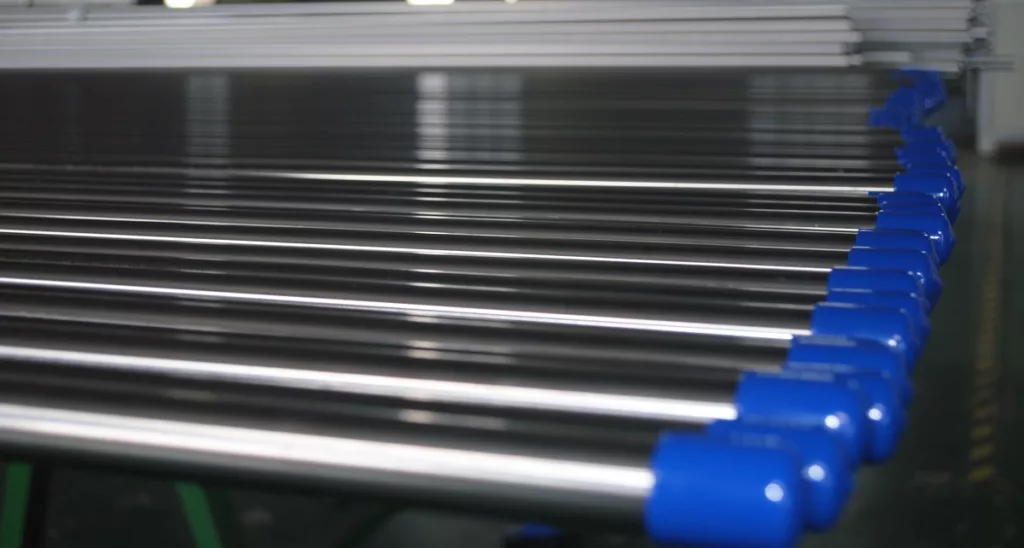

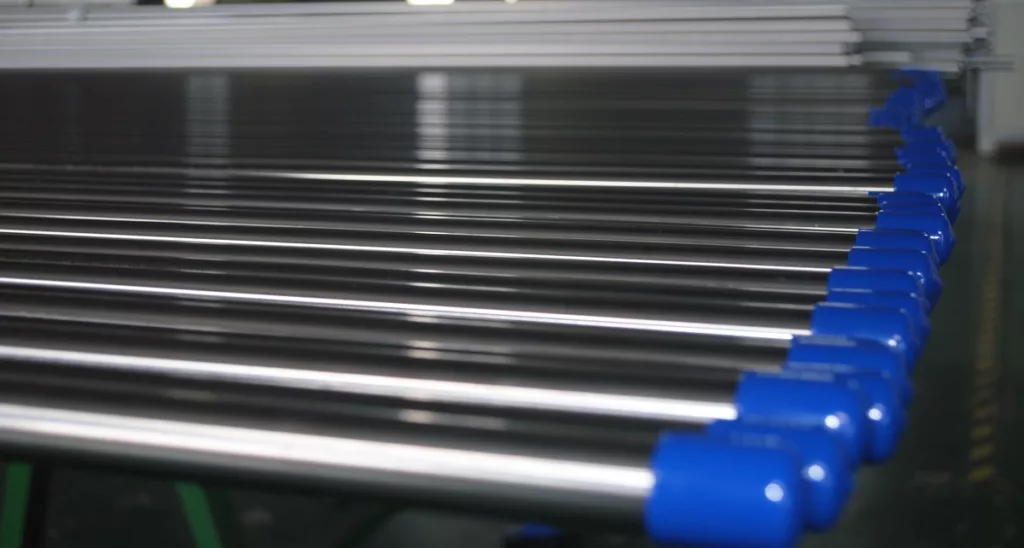

■ Tubing Packing: Tube end capped with plastic caps, each tube packed in a separated bag.

High purity tubing / UHP (Ultra-high purity) tubing: Product Descriptions

Here below is the detailed description of our factory’s stainless steel high purity and ultra high purity tubing.

- SPECIFICATION

- MATERIAL

- SURFACE

- SIZES

As one of the leading China high purity tubing manufacturers & suppliers, our factory produces and supplies stainless steel high purity and ultra-high purity tubes with most popular international standards. Here below is the typical list of standards we follow.

| Fractional Sizes Tubing | Metric and Imperial Sizes Tubes | |||||||||||||||||||||

ASTM A269 | ASTM A269 / A270 | |||||||||||||||||||||

The most popular material for our stainless steel high purity and ultra high purity tubing is SS TP316L, equivalent EN DIN 1.4404. Here below is the chemical composition.

| Element | Chemical Composition wt. % | ||||||||||||||||||||

| Chromium | 16.5 - 18.0 | ||||||||||||||||||||

| Nickel | 10.0 - 13.0 | ||||||||||||||||||||

| Molybdenum | 2.00 - 3.00 | ||||||||||||||||||||

| Manganese | max. 2.00 | ||||||||||||||||||||

| Silicon | max. 0.75 | ||||||||||||||||||||

| Carbon | max. 0.035➀ | ||||||||||||||||||||

| Sulfur | 0.005 to 0.012 (seamless); 0.030 max (thermocouple-cleaned) | ||||||||||||||||||||

| Phosphorus | 0.040 max. | ||||||||||||||||||||

Other stainless steel grades are available upon customer's request.

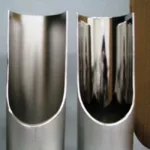

Younglee's stainless steel high purity tubing usually is supplied with bright annealed surface and mechanical polished surface, and our stainless steel Ultra-high purity tubing (UHP tube) has an electropolished inside surface finishing of roughness max Ra 0.25µm ( 10 µin.) .

| Surface Treatment | Inner Surface Roughness | Outer Surface Roughness |

| Bright Annealed (BA) | Ra 0.4μm (16Ra) to Ra 0.8μm (32Ra) upon request | Ra 0.8μm max |

| Mechanically Polished (MP) | Ra 0.4μm (16Ra) to Ra 0.8μm (32Ra)upon request | Ra 0.8μm max or upon request |

| ElectroPolished (EP) | EP SS tubing with Ra 0.25μm (10Ra) Max. | Ra 0.8μm max or upon request |

All the high purity & ultra high purity (UHP) tubes are with ends capped with PVC caps; every BA tube is packed individually in a single polyethylene bag, and EP stainless steel tubing (electropolished stainless steel tubing) is individually double bagged, then bulk bagged in a clean room, and then packed in wooden cases.

As a professional high purity tubing manufacturer & supplier, Younglee manufactures and supplies both imperial size and metric size of high purity tubing. Here below is some popular sizes.

Table 1. Imperial Sizes of high purity & Ultra-high purity (UHP) tubing

| Tube OD in. | Tube Wall in. | Ordering Code | Weight kg/m | Working Pressure psig |

| Stainless steel 316L Seamless high purity & ultra high purity (UHP) tubing | ||||

| 1/4 | 0.035 | ODT4-S-035-6M | 0.12 | 5100 |

| 3/8 | 0.035 | ODT6-S-035-6M | 0.19 | 3300 |

| 1/2 | 0.049 | ODT8-S-049-6M | 0.35 | 3700 |

| 3/4 | 0.065 | ODT12-S-065-6M | 0.71 | 3300 |

| 1 | 0.065 | ODT16-S-065-6M | 1.2 | 2400 |

Table 2. Metric sizes of high purity & Ultra-high purity (UHP) tubing

| Tube OD mm | Tube Wall mm | Legth m. | Ordering Code | Weight kg/m | Working Pressure bar |

| Seamless 316L Stainless Steel high purity & ultra high purity (UHP) tubing | |||||

| 6 | 1.0 | 6 | ODT6M-S-1.0M-6M | 0.125 | 420 |

| 8 | 1.0 | 6 | ODT8M-S-1.0M-6M | 0.175 | 310 |

| 10 | 1.0 | 6 | ODT10M-S-1.0M-6M | 0.225 | 240 |

| 12 | 1.0 | 6 | ODT12M-S-1.0M-6M | 0.275 | 200 |

| 18 | 1.5 | 6 | ODT18M-S-1.5M-6M | 0.619 | 200 |

Other sizes are available on customers' request, and normally the length our high purity tubing is 6 mtrs, other length is available on request.

High purity & Ultra-high purity tubing applications

Stainless steel high purity tubing and Ultra-high purity (UHP) tubes are widely used in applications where high cleanness, high purity and high performance are required, here below is a list of the typical applications.

- High purity liquid or high purity gas convey

- Clean gas supply system construction

- UHP tubes for semiconductor wafer processing and medical industries

- Laboratory gas convey

- Size Exclusion Chromatography

- Hydrophobic Interaction Chromatography

- Ion Exchange Chromatography

- Affinity Chromatography

- Reverse Phase Chromatography

- Biotechnology

- Pharmaceutical instrumentation

Besides stainless steel high purity & ultra high purity tubes and ultra high purity pipes, we also supply below high purity products.

Customers who are interested in high purity and ultra high purity (UHP) tubing and fittings, please contact us for more details.

Contact details:

EMAIL: [email protected]

TEL: 0086-(0)18612706695

- Ultra-high purity stainless steel fittings

- High purity stainless steel fittings

- Stainless steel ASME BPE Tube & fittings

- Stainless steel Coaxial tubing & COAX fittings

Questions & Answers

UHP tubing is the short for Ultra High Purity tubing. UHP tubing usually is electropolished stainless steel tubing with ultra high purity, cleanliness and smoothness inner surface. The inner surface roughness of UHP tubing can be as good as Ra0.25 μm or 10RA(10μin). The most popular material for UHP tubes is stainless steel 316L (EN 1.4404).

Our high performance stainless steel tubing factory is a leading China High purity & Ultra-high purity tubing manufacturer. Our high purity & UHP tubing has advantages as below.

- Top quality raw materials

Our raw material stainless steel are from China top quality stainless steel manufacturers such as Baosteel, Tisco, Youngxing. - TQM Quality Management system to ensure the quality

All working process are under control by our Total Quality Management system, which ensures the quality of the high purity & UHP tubes and pipes 100% meet customers’ requirements. - Our factory has a variety of professional inspection facilities, including:

Scanning Electron Microscope (SEM),Energy Dispersive Spectroscopy(EDS), Particle Counter, Surface Roughness Gauge, Micro Vickers, Metallography Microscope, Moisture Analyzer, Tensile Testing Machined etc. - Our UHP & high purity tubes and pipes are with high purity, high cleanliness, and high smoothness.

- High corrosion resistant performance

- Suitable for orbital welding

- Full size range and accept customized size

- Flexible and fast delivery time

If customer agrees or wishes, we will mark each tube with laser marking, the marking usually including:

- Manufacturer Name: Younglee (if the customer wants, we can also mark with themselves’ company name)

- Corresponding Standard as: ASTM A269/ A632/ A270; EN 10216-5

- Steel Grade: 316L / 1.4404

- Dimension: O.D(outer diameter) x W.T (wall thickness) x length

- Heat Number.

If the customer wish, the above markings will be on the packing bags or with a label. This is sometimes for the electro-polished stainless steel tubing.

Each tube will be capped in the ends with plastic caps, for BA and EP high purity tubing, every tube is packed individually in a single polyethylene bag; and every UHP electropolished tubing will be packed in double polyethylene bags. And then the well packed tubes will be put into a wooden case.

We can pack the high purity stainless steel tubing and ultra-high purity SS tubing in an class 10 clean room.

Our Bright annealed and electropolished (EP) high purity tubes & pipes are chemically cleaned and passivated to keep nonvolatile residue levels to comply with ASTM G93 or SEMI E 49.6.

The Ultra-High Purity (UHP) tubes &pipes are rinsed with 18MΩ di water and purged with 99.9995% filtered nitrogen and are packed in an class 10 clean room.

-e1677569150106.png)