-

Best solution for hydraulic tubing line installation and fastening

It is widely recognized in the field of hydraulic engineering that the reliable, suitable and good tubing line support is very important to keep the hydraulic systems efficient, leak-free and easy to maintain. And the solution for hydraulic tubing installation and fastening is one of the critical facts to assure the reliable tubing line support system.

Various kinds of pipe clamps are used for tube and pipe clamping in different industries under different applications. As we all know, there are three main purpose of clamping of hydraulic tube lines, which are reducing impact and vibration, reducing system noise and for pipe installing.

Hydraulic pipe clamps are one of the best solution for hydraulic tube line clamping, fastening, and installing. The unique structure of hydraulic pipe clamps ensures the clamps can greatly reduce the impact, vibration and noise, and they are more and more used in various hydraulic systems.

How to fasten the hydraulic tubes with hydraulic tube clamps to reduce the vibration?

Vibration is very harmful to hydraulic systems. Mechanical vibration can cause fatigue of the tube lines and other hydraulic parts, one of the most common adverse effects is that it will result to tube line failure. And the vibration will also cause tube fittings and connections to loosen, which will result in leaking of the hydraulic system.

So it is very important to fasten the hydraulic tubing lines with the right pipe clamping system to reduce the vibration, without right pipe clamping, vibration can be propagated through the system, resulting in a tube line failure that is far from the place where the main vibration source occurs.

To use the proper pipe clamping system, it is important to choose the right type of pipe clamps, but this is not enough, we also need to decide the right clamp space to clamping the tubes. The clamp space is the distance between to installed pipe clamps. Here below Table 1. is the recommended clamp distance layout for reducing vibration in hydraulic tubing and piping systems. For more details, please refer to our instruction of installing hydraulic pipe clamps.

Table 1. Recommended distance between two pipe clamps

| Tube O.D. (mm) | Distance(m) |

| 6 - 14 | 0.9 |

| 15 - 22 | 1.2 |

| 23 - 28 | 1.5 |

| 30 - 38 | 2.0 |

| 40 - 48.3 | 2.5 |

| 50 - 57 | 3.0 |

| 60.3 - 70 | 3.4 |

| 73 - 88.9 | 3.7 |

| 90 -108 | 4.0 |

| 114 - 165.1 | 4.3 |

| 140 - 165.1 | 5.0 |

| 168.3 - 220 | 5.5 |

How to choose the right type and material of hydraulic pipe clamps in applications?

There are many different types and materials of hydraulic pipe clamps.

According to different specifications, there are three main types as below:

- Light duty pipe clamps designed according to DIN 3015 part 1. This is the most popular and standard series of stauff type pipe clamps.

- Heavy duty pipe clamps designed and manufactured according to DIN 3015 part 2.

- Double pipe clamps / twin series pipe clamps designed and manufactured as per DIN 3015 part 3.

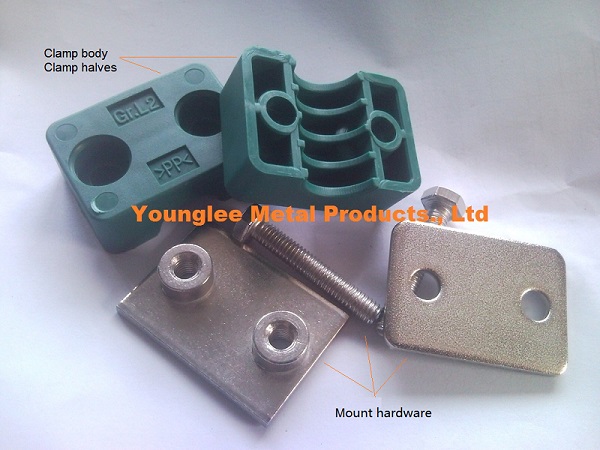

Normally the hydraulic pipe clamps are consist of metal mount hardware and clamp body (clamp halves).

The most popular materials of mount hardware are mild carbon steel, 304 stainless steel, 316 stainless steel; and the most popular materials of clamp body are Polypropylene, polyamide, Aluminum.

To choose the proper type and material of the hydraulic pipe clamps, engineers need to consider many factors such as strength of vibration, application, temperature and environment with high corrosion or not. Here below just some brief suggestions.

- Light series pipe clamps are mostly used to clamping hydraulic tubing, hoses, cables under normal (light) mechanical vibration applications, and they are only suitable for tube size O.D 6 mm to 102 mm.

- Heavy duty pipe clamps are mostly used to clamping hydraulic tubes and pipes under higher mechanical vibration (high pressure) applications. Heavy series pipe clamps are suitable for pipe size O.D 6 mm to 508 mm.

- Double pipe clamps are only suitable for tube size range O.D 6 mm to 42 mm. There are two holes on one clamp, so mostly we use this kind of pipe clamps to clamp two parallel tubes. Double pipe clamps are available in standard twin series and heavy twin series.

Stainless steel mounting hardware is usually for applications under corrosion environments such as chemical industries and marine industries, while for normal applications, we can use mild steel mount hardware with galvanized treatment or nickle coated treatment.

Hydraulic pipe clamps with Polypropylene clamp body is used for normal temperature applications, the working temperature range of Polypropylene clamp body is -30 centi degree to +90 centi degree.

Hydraulic pipe clamps with Polyamide clamp body is used for higher temperature applications with working temperature range of -30 to 120 centi degrees.

Aluminum pipe clamps are used for applications under the highest temperature, the working temperature can be up to 300 centi degree and even higher.

For applications under heavy vibration, we should use anti-vibration pipe clamps, for this type of pipe clamp, a rubber sleeve is used to further reduce the vibration in the hydraulic system.

As one of the most quick, safety and economic solution for pipe, tube, hose and cable installation and clamping in hydraulic systems, and pneumatic, lubrication systems, DIN 3015 series hydraulic pipe clamps will play more and more important roles in various industries. Customers who are interested, please contact us (email: [email protected]) for more details, or you can refer to our website of pipe clamps http://www.sino-alloy.com/portfolio-tube-clamps.html

Article written by: Jeremy Lon, copy right @ Younglee Metal Products Co., Ltd.